In my years of experience, I've seen countless customers struggle with inaccurate current measurements, leading to system failures and costly repairs.

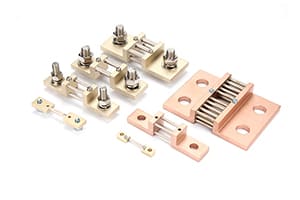

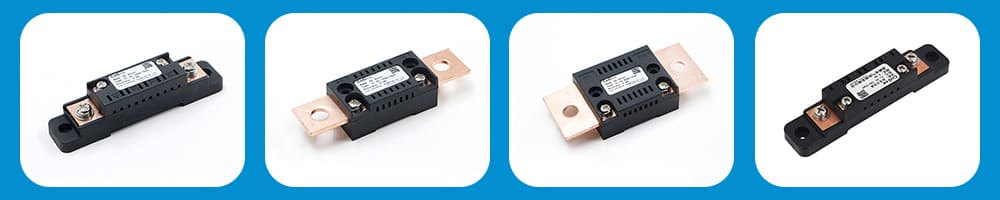

DC shunts are precision current-measuring devices that provide highly accurate readings, typically within ±0.1% accuracy. They offer stable performance, low temperature drift, and excellent reliability for various industrial applications.

As a manufacturer with over 30 years of experience in DC shunt production, I've witnessed the evolution of current measurement technology. The demand for precise current measurement has grown significantly, especially in emerging fields like electric vehicles and renewable energy. Today's DC shunts represent the perfect balance of accuracy, reliability, and cost-effectiveness that modern industries need. Let me share my insights about why DC shunts might be the right choice for your application.

What Benefits Do DC Shunts Offer?

Every week, I receive calls from engineers frustrated with their current measurement solutions. They're looking for something more reliable and accurate.

DC shunts excel in providing exceptional measurement stability, minimal power loss, and outstanding durability. Their simple yet effective design ensures consistent performance even in challenging industrial environments.

The benefits of DC shunts extend far beyond basic current measurement. From my extensive experience working with various industries, I've identified several key advantages that make DC shunts stand out. First, their high accuracy measurement capability, typically within ±0.1%, ensures precise current monitoring crucial for system optimization. The low resistance characteristics minimize power loss, making them highly energy efficient.

Another significant advantage is their remarkable stability over time. Unlike other current measurement devices, DC shunts maintain their accuracy even after years of operation. This stability comes from their simple construction and high-quality materials. They don't require regular recalibration, which significantly reduces maintenance costs and downtime.

Temperature performance is another area where DC shunts excel. With low temperature drift characteristics, they maintain accurate readings across a wide temperature range. This makes them ideal for applications where environmental conditions can vary significantly. Additionally, their high voltage tolerance allows them to handle substantial current loads without compromising accuracy.

How Do DC Shunts Compare?

When customers ask me about alternatives to DC shunts, I always emphasize the importance of understanding their specific needs and application requirements.

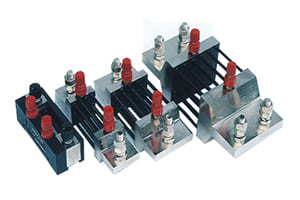

Compared to Hall effect sensors and current transformers, DC shunts offer superior accuracy, better stability, and lower maintenance costs. Their simple design and direct measurement principle make them more reliable for precise current monitoring.

Let me break down the key differences based on my experience in the field. DC shunts stand out in several crucial areas when compared to other current measurement solutions. First, unlike Hall effect sensors, DC shunts don't require external power supplies or complex signal conditioning circuits. This simplicity not only reduces potential points of failure but also leads to lower implementation costs.

Current transformers, while effective for AC measurements, cannot handle DC current measurements at all. DC shunts, however, excel in both DC and AC applications, though they're optimized for DC current measurement. The direct measurement principle of DC shunts also eliminates the measurement errors that can occur with indirect measurement methods.

In terms of long-term stability, DC shunts significantly outperform other solutions. While Hall effect sensors may require periodic recalibration and current transformers can suffer from core saturation issues, DC shunts maintain their accuracy specifications throughout their lifetime with minimal maintenance requirements.

Where Are DC Shunts Used?

Throughout my career, I've seen DC shunts transform various industries with their precise current measurement capabilities.

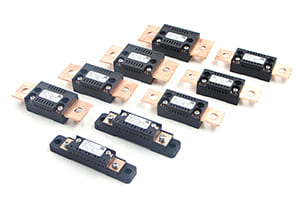

DC shunts find extensive applications in electric vehicles, renewable energy systems, battery management, and industrial automation. Their versatility and reliability make them essential components in modern power systems.

The applications for DC shunts are diverse and growing. In the electric vehicle industry, they play a crucial role in battery management systems, monitoring charging and discharging currents with high precision. This accuracy is essential for optimizing battery life and ensuring safe operation. The compact design of modern DC shunts makes them ideal for the space-constrained environments in EVs.

Renewable energy systems, particularly solar installations, rely heavily on DC shunts for accurate current measurement. They help monitor power generation efficiency and ensure optimal system performance. In industrial automation, DC shunts are used in motor control systems, power supplies, and various process control applications where precise current measurement is critical.

The UPS power system industry also benefits significantly from DC shunt technology. These devices help monitor battery health and system performance, ensuring reliable backup power when needed. Research laboratories and calibration facilities use high-precision DC shunts as reference standards for current measurement.

Conclusion

After three decades in the industry, I can confidently say that DC shunts remain the most reliable and cost-effective solution for precise current measurement. Their combination of high accuracy, stability, and durability makes them indispensable in modern industrial applications. Whether you're working in electric vehicles, renewable energy, or industrial automation, DC shunts offer the precision and reliability your application demands. The continued evolution of DC shunt technology, coupled with their proven track record, ensures they will remain a crucial component in current measurement applications for years to come.