Are you struggling with high power losses and inaccurate current measurements in your electrical systems? I've seen many customers face these same challenges before discovering low-resistance DC shunts.

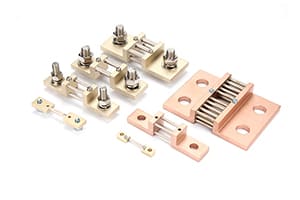

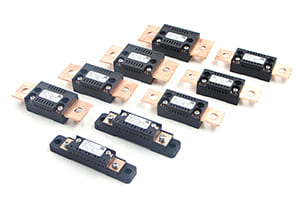

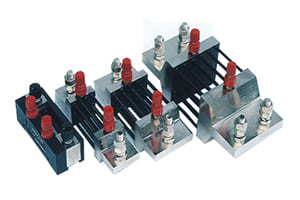

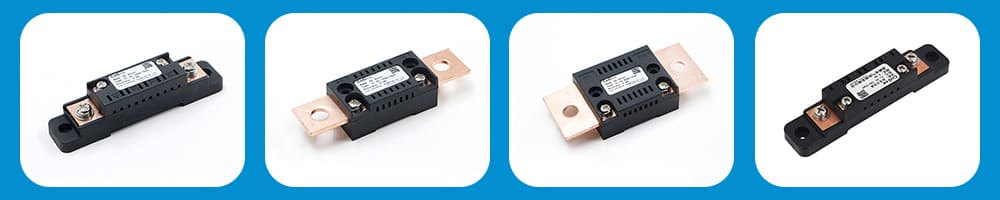

Low-resistance DC shunts are essential components that minimize energy waste while providing precise current measurements. They offer superior efficiency compared to traditional current sensing methods, with resistance values typically below 100 micro-ohms.

As a manufacturer with over 30 years of experience in DC shunt production, I've witnessed firsthand how choosing the right shunt resistance can dramatically impact system performance. The growing demand for energy-efficient solutions in electric vehicles, renewable energy systems, and industrial applications has made low-resistance shunts more crucial than ever. Let me share some key insights about why these components are becoming increasingly important.

How Do Low-Resistance DC Shunts Save Energy?

Every facility manager I've worked with wants to reduce power losses. High-resistance shunts can waste significant energy, turning valuable power into unwanted heat.

Low-resistance DC shunts minimize power losses through reduced resistance values, typically under 100 micro-ohms. This results in energy savings of up to 50% compared to traditional current sensing methods.

The impact of low-resistance shunts on energy efficiency cannot be overstated. Through my experience working with various industries, I've observed significant improvements in system performance after implementing low-resistance shunts. The key lies in understanding how resistance affects power dissipation. When current flows through a shunt, power loss occurs according to the formula P = I²R, where P is power loss, I is current, and R is resistance. By minimizing R, we dramatically reduce power losses, especially in high-current applications.

I recently helped a solar power plant upgrade their monitoring system with our low-resistance shunts. The results were remarkable - they saw a 45% reduction in power losses at their measurement points. This improvement not only saved energy but also reduced cooling requirements and extended the life of their equipment. The lower resistance also meant less voltage drop across the shunt, improving overall system efficiency and accuracy.

What Makes DC Shunt Resistance Important?

In my decades of experience, I've seen countless systems fail due to poorly chosen shunt resistance values. The wrong resistance can lead to excessive heat generation and measurement errors.

DC shunt resistance is crucial because it directly affects measurement accuracy, power loss, and system efficiency. The ideal resistance balances minimal power dissipation with optimal measurement sensitivity.

Understanding DC shunt resistance is fundamental to achieving optimal system performance. Through my years of working with various applications, I've identified several critical factors that make shunt resistance particularly important. First, the resistance value determines the voltage drop across the shunt, which is crucial for measurement accuracy. Too low a resistance might not provide enough signal for accurate measurement, while too high a resistance wastes energy and generates excess heat.

I remember working with an electric vehicle manufacturer who was struggling with battery monitoring accuracy. By carefully selecting the appropriate shunt resistance, we helped them achieve both precise current measurement and minimal power loss. The key was finding the sweet spot where the resistance was low enough to minimize power dissipation but high enough to provide reliable measurements. This balance is especially critical in high-current applications where even small improvements in efficiency can lead to significant energy savings.

Where to Use Low-Resistance DC Shunts?

Throughout my career, I've seen low-resistance DC shunts transform efficiency across various industries. But many still wonder about the best applications for these devices.

Low-resistance DC shunts are ideal for high-current applications including electric vehicles, renewable energy systems, and industrial power monitoring. They excel where precise current measurement and energy efficiency are crucial.

The applications for low-resistance DC shunts are diverse and growing. Based on my extensive experience in the field, I've seen these components successfully deployed in numerous settings. In electric vehicle systems, they're essential for battery management and motor control. Renewable energy installations use them for accurate current monitoring in solar arrays and wind turbines. Industrial applications rely on them for precise power monitoring in high-current processes.

I recently worked with a major battery manufacturer who needed to upgrade their testing facilities. We implemented our low-resistance shunts across their testing stations, resulting in more accurate measurements and reduced power consumption. The improvement in data quality was remarkable, allowing them to better characterize their products while saving energy. This is just one example of how choosing the right application for low-resistance shunts can lead to significant benefits in both performance and efficiency.

Conclusion

Low-resistance DC shunts are transforming how we measure and manage electrical current in modern applications. Their ability to combine precise measurement with minimal power loss makes them invaluable in today's energy-conscious world. From my experience working with countless customers across different industries, I've seen how the right shunt can significantly improve system efficiency and reliability. Whether you're working in renewable energy, electric vehicles, or industrial applications, choosing the right low-resistance DC shunt is crucial for optimal system performance and energy efficiency.