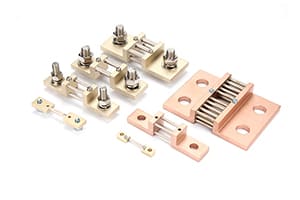

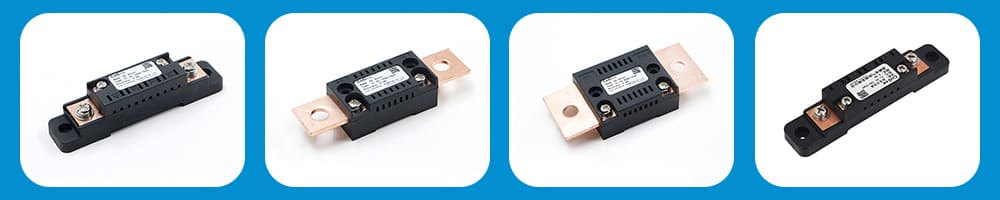

In my 30 years of experience with DC shunts, I've seen countless measurement failures due to poor maintenance. These failures can cost companies thousands in damaged equipment and downtime.

Proper DC shunt maintenance is crucial for maintaining measurement accuracy and extending device lifespan. Regular inspection, cleaning, and calibration can prevent 95% of common issues and ensure continuous reliable performance.

As a DC shunt manufacturer since 1992, I've helped countless clients optimize their maintenance routines. While DC shunts are relatively simple devices, they require specific care to maintain their high precision. Let me share the essential maintenance practices I've developed over three decades in the industry.

How to Maintain DC Shunt Accuracy?

The accuracy of your DC shunt can drift over time, leading to unreliable measurements. I've seen this cause serious problems in critical applications like battery management systems.

To maintain DC shunt accuracy, implement monthly calibration checks, ensure proper temperature control, and verify connection integrity. These steps can help maintain accuracy within ±0.1% and prevent measurement drift.

Maintaining DC shunt accuracy requires a systematic approach. First, establish a regular calibration schedule based on your application's requirements. For high-precision applications, I recommend monthly checks using a certified reference standard. Temperature control is equally crucial - install your shunt in a well-ventilated area and monitor ambient temperature variations. Keep detailed records of calibration results to track any drift patterns.

Connection integrity is another critical factor. Loose or corroded connections can introduce resistance variations that affect accuracy. Inspect all terminals monthly, checking for proper torque settings and signs of oxidation. In harsh environments, consider applying protective coatings to prevent corrosion.

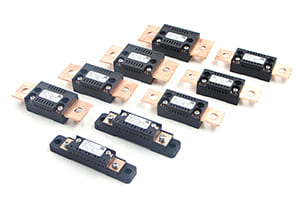

What DC Shunt Care Is Required?

Daily visual inspections have saved my clients from major system failures. One customer avoided a complete production line shutdown by spotting early signs of connection degradation.

Regular DC shunt care includes cleaning connections, checking mounting stability, and monitoring environmental conditions. These basic maintenance tasks can prevent 90% of common failures and extend service life significantly.

Proper DC shunt care encompasses several key areas. Environmental protection is crucial - ensure your shunt is protected from moisture, dust, and excessive vibration. Install appropriate enclosures and verify their integrity regularly. Clean the shunt and surrounding area monthly using appropriate electrical contact cleaners.

Mounting stability directly affects measurement accuracy. Check mounting hardware monthly for proper torque and signs of vibration damage. Use appropriate lock washers and thread-locking compounds in high-vibration applications. Pay special attention to thermal expansion effects in applications with wide temperature variations.

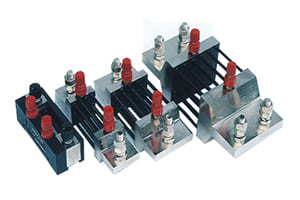

Why Service DC Shunts Regularly?

A client once ignored regular servicing until their entire power monitoring system failed. The cost of emergency repairs and downtime far exceeded what preventive maintenance would have cost.

Regular DC shunt servicing prevents unexpected failures, maintains measurement accuracy, and extends equipment life. Scheduled maintenance typically costs 75% less than emergency repairs and prevents costly downtime.

Regular servicing provides numerous benefits beyond basic maintenance. Professional inspection can identify potential issues before they cause failures. This includes checking for thermal stress indicators, analyzing connection quality using thermal imaging, and verifying calibration against certified standards.

During service visits, technicians can also optimize installation conditions. This might involve improving ventilation, upgrading mounting hardware, or recommending protection against environmental factors. Regular service records also help track long-term performance trends and predict potential failures before they occur.

Conclusion

Proper DC shunt maintenance is essential for reliable current measurement and long-term performance. Through my three decades of experience, I've found that regular maintenance, careful attention to installation conditions, and professional servicing are key to maximizing shunt lifespan and accuracy. By following these maintenance guidelines, you can ensure your DC shunts provide reliable service for years to come. Remember, the small investment in regular maintenance prevents costly failures and ensures continuous accurate measurements in your critical applications.