Are you dealing with challenging high-current measurement applications? Many engineers struggle to find reliable solutions for accurate high-current monitoring.

DC shunts excel in high-current applications by providing accurate measurements up to thousands of amperes while maintaining low power losses. Their robust design and precise calibration ensure reliable performance under extreme current loads.

As a manufacturer who has specialized in high-current DC shunts for over three decades, I've helped countless customers solve their most challenging current measurement problems. The right shunt can make the difference between stable operation and system failure. Let me share my insights about why DC shunts are the optimal choice for high-current applications.

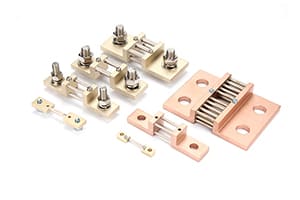

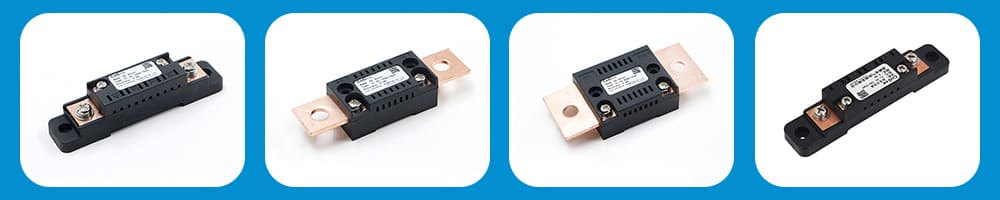

What DC Shunt Features Handle High Current?

Many customers ask about the specific features needed for high-current applications. Choosing the wrong features can lead to measurement errors or system failures.

High-current DC shunts feature specialized heat dissipation designs, robust connection terminals, and low resistance values. These features enable reliable operation at currents exceeding 5000 amperes.

Through my years of experience designing high-current shunts, I've identified critical features that ensure reliable performance. Advanced heat dissipation techniques prevent thermal drift, while robust terminal designs ensure stable connections under high current loads. The low resistance values minimize power losses and heat generation.

I recently worked with an aluminum smelting plant that needed precise current measurement for their 8000-ampere process lines. By implementing our specially designed high-current shunts with enhanced cooling features, they achieved stable measurements with less than 0.1% error. The improved accuracy helped them optimize their process efficiency and reduce energy costs.

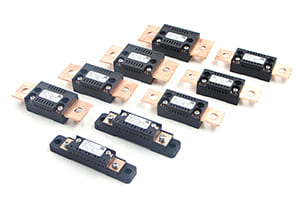

How Do DC Shunts Manage Power Loads?

Understanding power load management is crucial for high-current applications. Many users underestimate the challenges of handling large power loads.

DC shunts manage high power loads through optimized heat dissipation, precise resistance values, and robust construction. These characteristics enable them to handle continuous high currents while maintaining measurement accuracy.

Based on my extensive experience with high-power applications, effective power load management requires a comprehensive approach. The shunt's design must balance minimal power dissipation with accurate measurement capability. Proper sizing and installation are crucial for optimal performance.

I remember helping an electric vehicle charging station manufacturer solve their power management issues. Their original solution couldn't handle the sustained high currents during fast charging. After implementing our specialized high-current shunts with advanced cooling design, they achieved stable operation at 400A continuous current, with peaks up to 800A during charging cycles.

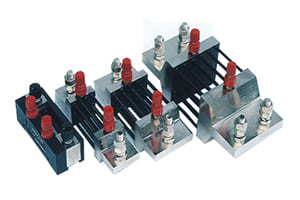

Where to Use High-Current DC Shunts?

Throughout my career, I've seen high-current DC shunts successfully deployed in various demanding applications. Understanding suitable applications is key to successful implementation.

High-current DC shunts are ideal for industrial processes, electric vehicle charging, renewable energy systems, and power distribution applications. They excel in environments requiring precise measurement of large currents.

The applications for high-current DC shunts are diverse and growing. From my experience working with various industries, these components are crucial in applications requiring precise high-current measurement. They're particularly valuable in modern applications like electric vehicle charging stations, solar power inverters, and industrial electroplating processes.

Recently, I assisted a data center in implementing high-current shunts for their power distribution system. The shunts provided accurate monitoring of their 2000A main feeds, enabling better load balancing and energy management. This implementation improved their power usage effectiveness (PUE) by 15% and enhanced their ability to prevent overload conditions.

Conclusion

High-current DC shunts are essential components for modern power systems requiring precise current measurement at high amperage levels. Their robust design, accurate measurement capabilities, and reliable performance make them the ideal choice for demanding applications. My years of experience have shown that selecting the right high-current DC shunt solution is crucial for system reliability and efficiency. Whether you're working with industrial processes, renewable energy systems, or electric vehicle charging stations, proper selection and implementation of high-current DC shunts will ensure optimal system performance.