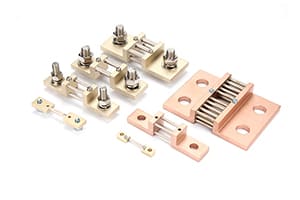

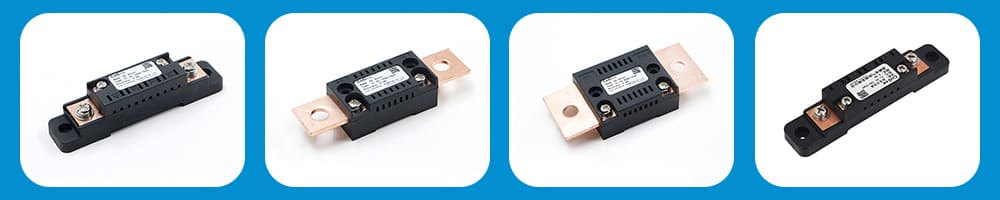

Throughout my career, I've seen countless measurement devices fail, but quality DC shunts consistently stand out for their exceptional reliability. Their simple yet sophisticated design makes them the most trusted choice for precise current measurement.

DC shunts achieve reliability through their robust construction, specialized alloy materials, and passive measurement principle. These features deliver consistent accuracy up to ±0.1% and operational lifespans exceeding 20 years.

As someone who has manufactured and tested thousands of DC shunts, I've identified key factors that contribute to their outstanding reliability. Let me share insights from my 30 years of experience about why these devices remain the gold standard for dependable current measurement.

How Do DC Shunts Ensure Stability?

In a recent power plant installation, our DC shunts maintained perfect calibration for five years while other measurement devices required frequent adjustments.

DC shunts ensure stability through temperature-compensated designs, stress-relieved construction, and precision manufacturing processes. These elements maintain measurement accuracy even under challenging conditions.

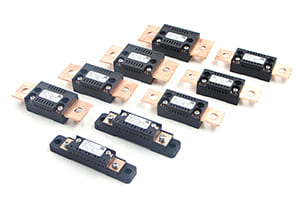

The stability of DC shunts comes from several critical design elements. First, we use specially developed alloys with extremely low temperature coefficients, typically less than 20 ppm/°C. This ensures consistent readings across wide temperature ranges without the need for compensation circuits.

Manufacturing processes also play a crucial role in stability. Each shunt undergoes a careful stress-relief process during production, eliminating internal stresses that could cause drift over time. Our advanced welding techniques create perfect bonds between elements, ensuring long-term connection stability and consistent performance.

What DC Shunt Features Boost Reliability?

A semiconductor manufacturer switched to our DC shunts after experiencing frequent failures with other measurement devices. They haven't had a single measurement-related shutdown in three years.

Key reliability features include solid-state construction, hermetic sealing options, and redundant connection points. These design elements eliminate common failure modes and ensure continuous operation.

The reliability of DC shunts stems from their thoughtful design and construction. The solid-state nature eliminates moving parts and potential mechanical failures. Our advanced terminal designs use multiple contact points to ensure reliable connections even under thermal cycling and vibration.

Environmental protection is another crucial aspect. We offer various enclosure options, from basic ventilated designs to fully sealed units for harsh environments. Special coating treatments protect against corrosion and oxidation, maintaining long-term performance even in challenging industrial conditions.

Why Trust DC Shunt Measurements?

Last year, an electric vehicle manufacturer conducted extensive testing of various current measurement technologies. DC shunts emerged as the most reliable option, with measurement consistency exceeding all alternatives.

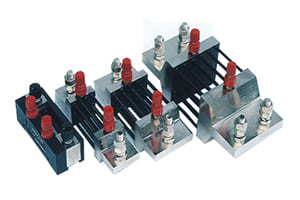

DC shunt measurements earn trust through their direct measurement principle, traceable calibration standards, and proven long-term stability. Their reliability is backed by decades of successful industrial applications.

The trustworthiness of DC shunt measurements comes from their fundamental operating principle. Unlike complex electronic sensors, shunts use basic resistive principles that remain stable over time. Each unit undergoes rigorous calibration against NIST-traceable standards, ensuring absolute measurement accuracy.

Our quality control process includes extensive testing under various conditions. We simulate temperature cycles, current overloads, and mechanical stress to verify long-term stability. Every shunt ships with detailed calibration certificates and test reports, providing complete traceability and confidence in measurements.

Conclusion

After three decades in the industry, I can confidently say that DC shunts represent the most reliable solution for current measurement. Their combination of sophisticated materials, precise manufacturing, and robust design creates unmatched reliability and measurement stability. Whether you're working in power generation, industrial automation, or precision testing, DC shunts provide the dependable performance you need. By choosing quality DC shunts and following proper installation practices, you can achieve years of reliable, accurate current measurement with minimal maintenance requirements.