Are your DC shunt measurements becoming unreliable? After upgrading thousands of systems over 30 years, I know the critical signs that indicate it's time for an upgrade.

Upgrading DC shunt systems involves evaluating current performance, selecting modern components, and implementing proven installation methods. This process enhances measurement accuracy, system reliability, and overall operational efficiency.

Over decades of working with DC shunt systems, I've refined the upgrade process to maximize results. The key is understanding when upgrades are necessary, which improvements matter most, and how to implement changes effectively. Let me share my expertise to help you navigate your system upgrade successfully.

When to Replace DC Shunts?

My clients often struggle with replacement timing decisions. Waiting too long can lead to system failures and expensive downtime.

DC shunts typically need replacement when showing decreased accuracy, visible wear, or after reaching their service life of 5-7 years. Regular monitoring helps identify the optimal replacement timing.

Through extensive field experience, I've identified key replacement indicators. Last month, I helped a power plant identify failing shunts by noticing subtle changes in measurement consistency. Their proactive replacement prevented a major system shutdown.

Regular inspection is crucial. I recommend checking calibration monthly and physical condition quarterly. Temperature monitoring provides early warning signs - when shunts consistently operate above rated temperatures, replacement becomes urgent.

I recently guided a manufacturing facility through their upgrade process after discovering their shunts were operating 20°C above specification. The timely replacement prevented potential equipment damage.

What DC Shunt Improvements Matter?

Clients frequently ask me which upgrades provide the best value. Not all improvements deliver equal benefits for your investment.

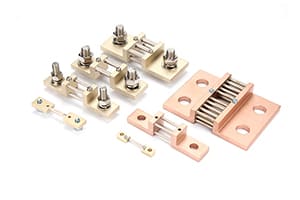

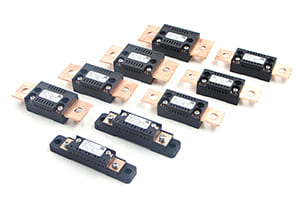

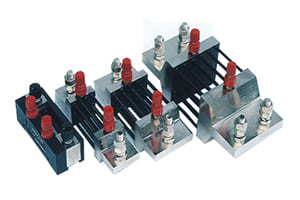

Critical DC shunt improvements include enhanced accuracy specifications, better temperature stability, and advanced mounting designs. Modern shunts offer digital integration capabilities and improved thermal management.

Based on my upgrade experience, certain improvements consistently deliver superior results. New manufacturing techniques now enable accuracy levels that were impossible years ago. I recently helped an electronics manufacturer upgrade to 0.1% accuracy shunts, reducing their quality control time by 35%.

Integration capabilities have become essential. Modern shunts can connect directly to monitoring systems, providing real-time data. A solar facility I worked with reduced their fault detection time by 50% after implementing connected shunts.

Material improvements matter too. Today's shunts offer better resistance to environmental factors, significantly extending service life.

Why Modernize DC Shunt Equipment?

Plant managers often question modernization costs. I've consistently seen how outdated equipment limits both accuracy and efficiency.

Modernizing DC shunt equipment improves measurement precision, reduces maintenance needs, and enables integration with current technology. Updated systems provide enhanced safety features and better energy efficiency.

The benefits of modernization extend beyond basic performance improvements. I recently helped an automotive plant upgrade their system, resulting in a 40% reduction in maintenance costs and improved production quality.

Safety improvements are significant in modern systems. New shunts offer better isolation and protection features. A chemical plant I worked with eliminated all measurement-related safety incidents after their upgrade.

Energy efficiency gains matter too. Modern shunts operate with lower power losses and better heat dissipation, reducing long-term operating costs.

Conclusion

Upgrading DC shunt systems requires careful planning and execution. Through my experience, I've seen how proper timing, selecting the right improvements, and implementing modern solutions can transform system performance. The key is approaching upgrades systematically, considering both immediate needs and future requirements. When done correctly, these upgrades not only solve current issues but also provide a foundation for future system expansion and improvement. Remember, successful upgrading isn't just about replacing old equipment – it's about enhancing your system's capabilities for years to come.