Is your DC shunt system showing signs of age or decreased performance? After testing thousands of systems, I know exactly when and how to upgrade for optimal results.

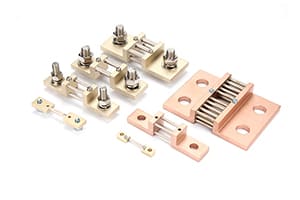

Upgrading DC shunt systems involves evaluating current performance, identifying improvement areas, and implementing modern solutions. The process requires careful assessment of existing equipment, selection of compatible upgrades, and proper installation techniques.

Throughout my 30 years in the industry, I've guided countless clients through successful system upgrades. The key is understanding when upgrades are necessary and which improvements will provide the most value. Let me share my expertise to help you make informed decisions about upgrading your DC shunt system.

When to Replace DC Shunts?

Every week, I receive calls from worried customers about their aging DC shunts. Knowing when to replace them can prevent costly system failures.

DC shunts typically need replacement when showing signs of physical damage, inconsistent readings, or after 5-10 years of continuous use. Regular monitoring of accuracy and performance helps identify the right time for replacement.

Through my years of experience, I've identified several clear indicators that signal the need for DC shunt replacement. Physical signs include discoloration around terminals, loose connections, or visible corrosion. Performance issues often manifest as drift in measurements or inconsistent readings.

Temperature monitoring is crucial - if your shunt runs consistently hotter than designed, it's time for an upgrade. I recently helped a client who ignored these signs, resulting in a complete system shutdown. Regular calibration checks can reveal degrading accuracy, another key replacement indicator.

I always recommend maintaining detailed performance logs. This helps track gradual changes that might otherwise go unnoticed. When accuracy falls below 99% of original specifications, replacement should be considered.

What DC Shunt Improvements Matter?

Clients often ask me about the most impactful upgrades for their systems. Not all improvements offer equal value for your investment.

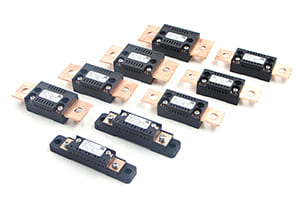

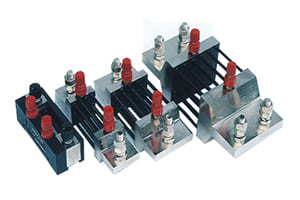

Key DC shunt improvements include enhanced accuracy ratings, better temperature stability, and improved mounting designs. Modern shunts offer digital integration capabilities and advanced thermal management features.

In my experience, the most valuable improvements focus on three core areas: accuracy, reliability, and integration capabilities. Modern shunts offer remarkable advances in each of these aspects.

Accuracy improvements come from better materials and manufacturing processes. I've seen new manganin alloys that provide stability up to 0.01% - a significant upgrade from older 0.5% models. Temperature compensation has also evolved, with new designs maintaining accuracy across wider temperature ranges.

Integration capabilities matter more than ever. New shunts can include digital outputs, remote monitoring features, and advanced diagnostic capabilities. I recently helped a factory upgrade to smart shunts that provide real-time data to their control system.

Why Modernize DC Shunt Equipment?

Many of my clients hesitate to modernize their equipment, wondering if the benefits justify the investment. I've seen firsthand how modernization pays off.

Modernizing DC shunt equipment improves measurement accuracy, reduces maintenance costs, and enables integration with modern control systems. Updated equipment also provides better safety features and energy efficiency.

The decision to modernize DC shunt equipment goes beyond simple replacement. It's about future-proofing your system and taking advantage of technological advances. I've guided numerous facilities through this process, seeing remarkable improvements in their operations.

Modern equipment offers enhanced safety features that older systems lack. This includes better isolation, improved thermal management, and more robust overload protection. One of my clients reduced their maintenance downtime by 60% after upgrading to modern shunts with predictive maintenance capabilities.

Energy efficiency improvements are another key benefit. New shunts operate with lower power losses and better heat dissipation. This translates to reduced operating costs and longer equipment life.

Conclusion

Upgrading DC shunt systems is a critical decision that impacts measurement accuracy, system reliability, and operational efficiency. Through my experience, I've seen how proper timing of replacements, focus on meaningful improvements, and strategic modernization can transform system performance. The key is to approach upgrades systematically, considering both immediate needs and future requirements. When done correctly, these upgrades not only solve current issues but also provide a foundation for future system expansion and improvement. Remember, the goal isn't just to replace old equipment, but to enhance your system's capabilities for years to come.