In my decades of experience, I've seen many system failures caused by improper shunt installation. Even the highest quality DC shunts can't perform correctly if installed wrongly.

Correct DC shunt installation requires proper mounting, precise connection techniques, and careful attention to environmental factors. Following proper installation procedures ensures optimal performance and measurement accuracy.

Through years of supporting customers with installation challenges, I've developed comprehensive guidelines for proper shunt installation. Let me share critical insights about installation procedures that ensure optimal performance and reliability.

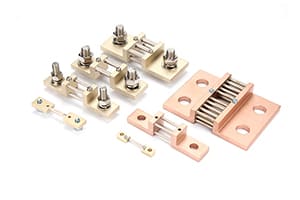

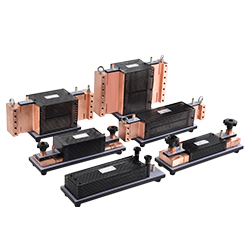

What Are DC Shunt Mounting Requirements?

Every installation project I oversee starts with proper mounting considerations. Poor mounting can lead to measurement errors and reduced system reliability.

DC shunts require specific mounting conditions including proper orientation, stable mounting surfaces, and adequate ventilation. These requirements ensure measurement accuracy and thermal stability.

Proper mounting is crucial for shunt performance. We've developed specific mounting guidelines based on extensive field experience. Our recommendations cover orientation, spacing, and surface preparation requirements.

The mounting system must provide both mechanical stability and thermal management. We use specialized mounting brackets that ensure proper alignment and heat dissipation. Each installation considers factors like vibration, thermal expansion, and accessibility for maintenance.

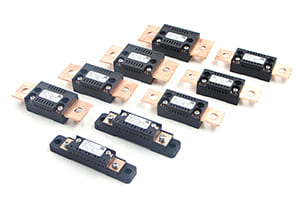

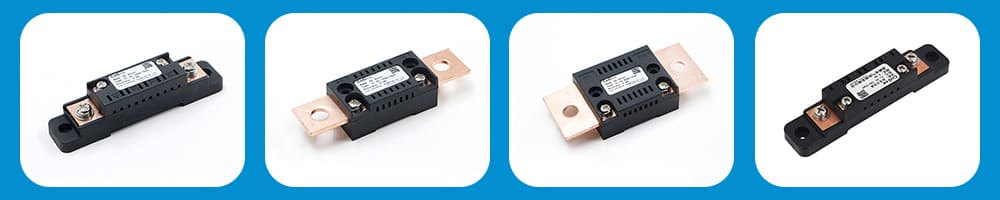

How to Connect DC Shunts Properly?

Throughout my career, I've found that connection quality significantly impacts measurement accuracy. Proper connection techniques are essential for reliable performance.

DC shunts must be connected with clean, tight connections using appropriate hardware and torque specifications. Proper connection ensures low contact resistance and stable measurements.

Connection quality affects both accuracy and reliability. Our installation guides specify proper terminal preparation and connection techniques. We recommend specific torque values and connection hardware for different current ranges.

Recent innovations in our connection designs include self-aligning terminals and temperature-stable connection systems. These features help maintain connection quality over time. Our testing has shown that proper connections can significantly extend system lifetime.

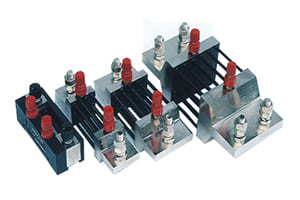

Why Does DC Shunt Installation Matter?

In my consulting work, I often explain how installation quality directly affects system performance. Proper installation is crucial for achieving specified accuracy and reliability.

DC shunt installation matters because it directly impacts measurement accuracy, system reliability, and safety. Proper installation ensures optimal performance and prevents measurement errors.

Installation quality affects every aspect of shunt performance. We've documented how proper installation practices improve measurement accuracy and system reliability. Our research shows that installation quality can impact measurement accuracy by up to 0.5%.

Proper installation includes considerations for environmental protection and maintenance access. We provide detailed guidelines for different installation environments. These practices ensure long-term reliability and maintain measurement accuracy.

Conclusion

Correct DC shunt installation is crucial for system performance and reliability. Through proper mounting, connection techniques, and attention to installation details, these devices can provide years of accurate service. My experience has shown that following proper installation procedures is as important as selecting the right shunt. As measurement requirements become more demanding, the importance of proper installation grows. Taking the time to install DC shunts correctly ensures optimal performance and long-term reliability.