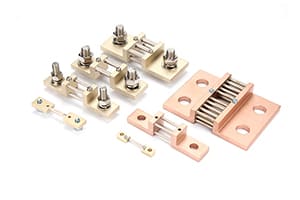

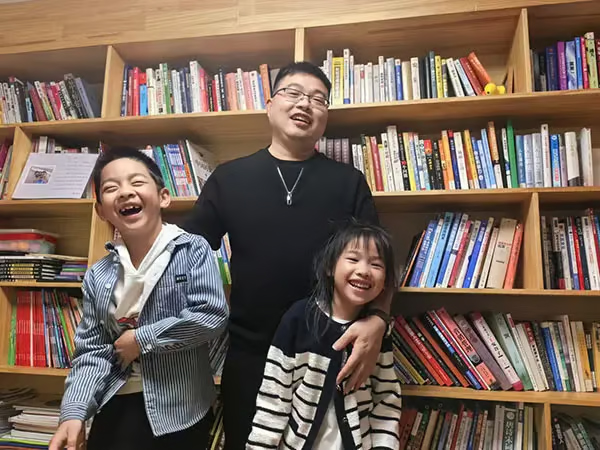

In my 30 years of manufacturing DC shunts, customers often ask about product lifespan. Without proper maintenance and selection, even high-quality shunts can fail prematurely.

DC shunts typically last 10-15 years when properly specified and maintained. However, their lifespan depends heavily on operating conditions, installation quality, and maintenance practices. High-quality shunts can exceed 20 years of service.

Through decades of experience in the industry, I've observed how various factors affect shunt longevity. The lifespan of a DC shunt isn't just about the component itself - it's about how well it's matched to the application, installed, and maintained. Let me share my insights on maximizing shunt lifetime and ensuring reliable long-term performance.

What Affects DC Shunt Lifespan?

Every week, I encounter cases where environmental conditions and usage patterns dramatically impact shunt life. Understanding these factors is crucial for extending service life.

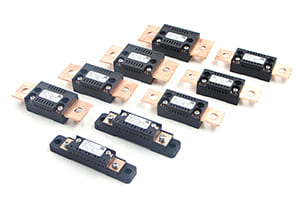

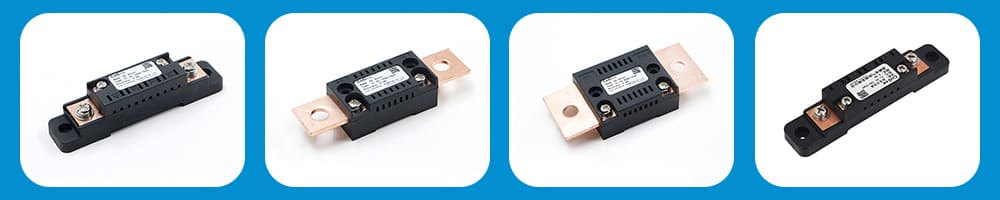

DC shunt lifespan is primarily affected by operating temperature, current levels, environmental conditions, and installation quality. These factors can reduce service life by up to 50% if not properly managed.

Through extensive field experience, I've identified key factors that impact shunt longevity. Temperature cycling causes thermal stress that can gradually degrade performance. Excessive current loads can lead to thermal damage and accelerated aging. Environmental factors like humidity and corrosive atmospheres can also significantly reduce lifespan.

Our research has shown that installation quality plays a crucial role. Proper mounting techniques reduce mechanical stress and improve heat dissipation. We've developed specific installation guidelines based on real-world performance data, helping customers maximize their shunt's service life.

How to Maximize DC Shunt Duration?

Throughout my career, I've helped countless clients extend their shunt lifespans through proper selection and maintenance. The right approach can significantly increase service life.

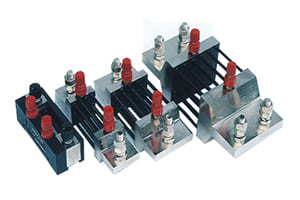

Maximizing DC shunt duration requires proper sizing, installation, regular maintenance, and environmental protection. Following best practices can extend service life by 30-50% beyond typical expectations.

Based on extensive field experience, we've developed comprehensive guidelines for maximizing shunt lifespan. Proper sizing ensures the shunt operates within its designed parameters. Our latest designs include enhanced thermal management features and corrosion-resistant materials that significantly extend service life.

We recommend regular inspection and maintenance schedules based on application requirements. This includes checking connection integrity, cleaning procedures, and environmental protection measures. Our data shows that following these guidelines can dramatically improve long-term reliability and performance.

When Should DC Shunts Be Replaced?

In my consulting work, I often help clients determine the optimal replacement timing for their shunts. Waiting too long can lead to system failures and safety risks.

DC shunts should be replaced when showing signs of physical damage, declining accuracy, or reaching their recommended service life. Regular accuracy testing can help determine replacement timing.

Through years of field experience, I've identified clear indicators that signal when replacement is needed. Physical signs include discoloration, corrosion, or loose connections. Performance indicators include drift in measurements or increased temperature during operation.

We've developed specific testing procedures to evaluate shunt condition and performance. Our latest diagnostic tools can help predict remaining service life based on operating history and current performance. This proactive approach helps prevent unexpected failures and maintains system reliability.

Conclusion

Understanding DC shunt lifespan is crucial for maintaining reliable measurement systems. Through proper selection, installation, and maintenance, these devices can provide many years of accurate service. My experience has shown that following best practices for installation and maintenance can significantly extend service life. Regular monitoring and timely replacement ensure continuous system reliability and safety. As measurement requirements become more demanding, choosing high-quality shunts and following proper maintenance procedures becomes increasingly important for achieving optimal performance and longevity.