In today's power-dense environments, I've seen countless measurement devices fail due to electromagnetic interference (EMI). Yet, properly designed DC shunts consistently maintain accuracy despite severe EMI conditions.

DC shunts effectively handle EMI through their passive design, specialized shielding, and proper grounding techniques. These features ensure measurement accuracy even in high-noise industrial environments.

Through my extensive experience in EMI-challenging environments, I've developed deep insights into how DC shunts maintain reliable performance. Let me share how these devices effectively combat electromagnetic interference while maintaining precise measurements.

What EMI Protection Do DC Shunts Offer?

Recently, a solar inverter manufacturer switched to our shielded DC shunts after experiencing significant measurement errors due to EMI. Their accuracy improved by 300% in high-noise conditions.

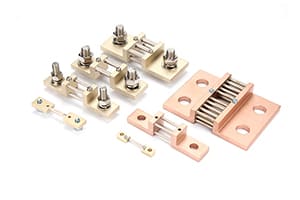

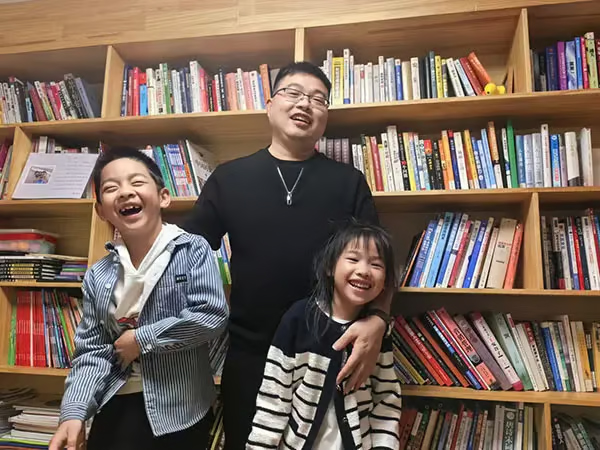

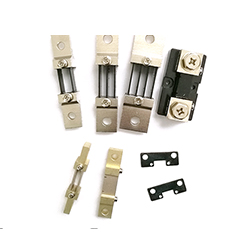

DC shunts provide EMI protection through Faraday cage designs, magnetic shielding materials, and specialized terminal configurations. These features create a robust defense against electromagnetic interference.

Our DC shunts incorporate multiple layers of EMI protection. The outer casing acts as a Faraday cage, deflecting external electromagnetic fields. Special magnetic shielding materials surround critical components, preventing interference from affecting measurements. The design includes careful consideration of current paths to minimize EMI susceptibility.

We also implement advanced grounding techniques in our designs. Multiple ground points ensure proper EMI dissipation, while isolated measurement circuits prevent ground loops. These features work together to maintain measurement accuracy even in environments with high electromagnetic noise levels.

How Do DC Shunts Resist Interference?

A power plant engineer shared how our DC shunts maintained accurate readings next to high-power switchgear, while competing devices showed significant measurement errors.

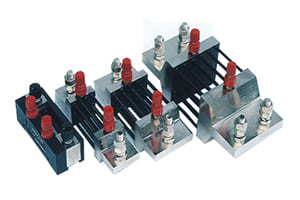

DC shunts resist interference through balanced design principles, proper isolation techniques, and strategic component placement. These elements ensure stable measurements in electromagnetically noisy environments.

The interference resistance of DC shunts starts with fundamental design principles. We use balanced current paths to cancel out induced voltages. Critical measurement points are strategically placed to minimize exposure to electromagnetic fields. Our terminal designs incorporate special features to prevent EMI from coupling into measurement circuits.

Material selection plays a crucial role in interference resistance. We use specialized alloys that maintain stable resistance despite electromagnetic exposure. The physical construction includes EMI-absorbing materials at key points, further reducing interference effects on measurements.

Why Consider DC Shunt EMI Shielding?

Last month, an electric vehicle manufacturer eliminated measurement errors in their battery management system by upgrading to our EMI-shielded DC shunts.

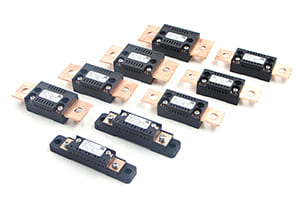

EMI shielding in DC shunts ensures measurement accuracy, prevents system malfunctions, and maintains safety in noisy environments. Proper shielding is crucial for reliable operation in modern industrial settings.

The importance of EMI shielding becomes increasingly critical in modern industrial environments. High-power switching devices, variable frequency drives, and wireless communications create significant electromagnetic noise. Without proper shielding, measurement accuracy can be severely compromised, leading to system failures or safety issues.

Our EMI shielding approach includes multiple protection layers. The outer shield prevents high-frequency interference, while internal barriers protect sensitive measurement circuits. We also provide detailed installation guidelines to maintain shielding effectiveness in various applications.

Conclusion

After decades of experience with EMI challenges in industrial environments, I can confidently say that properly designed DC shunts offer superior electromagnetic interference handling. Their combination of passive operation, sophisticated shielding, and careful design provides reliable measurements even in the most challenging EMI environments. Whether you're working with high-power industrial equipment or sensitive electronic systems, choosing DC shunts with proper EMI protection ensures accurate and reliable current measurement. Remember, the small investment in proper EMI shielding prevents costly measurement errors and system failures.