After witnessing several costly accidents due to non-compliant shunts, I've learned that understanding safety standards isn't just about compliance - it's about protecting lives and equipment.

DC shunt safety standards encompass voltage isolation, temperature ratings, and installation requirements. Key standards include UL 508A for industrial control equipment, IEC 61010 for measurement devices, and ISO 17025 for calibration accuracy.

Throughout my 30 years in the industry, I've helped countless clients navigate the complex landscape of safety standards. Let me share critical insights about safety requirements that every DC shunt user must understand to ensure safe and compliant operations.

Which Certifications Do DC Shunts Need?

Recently, a client's insurance claim was denied because their DC shunts lacked proper certification. This oversight cost them millions in equipment damage and business interruption.

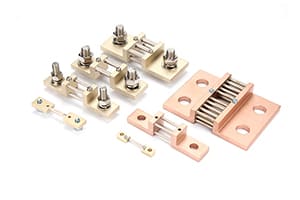

Essential DC shunt certifications include UL recognition, CE marking, RoHS compliance, and ISO 9001 quality management certification. These certifications ensure safety, reliability, and environmental compliance.

The certification landscape for DC shunts is comprehensive and varies by region and application. In North America, UL recognition is crucial, particularly UL 508A for industrial control equipment. European markets require CE marking, demonstrating compliance with all relevant EU directives, including Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) requirements.

For global markets, additional certifications may be necessary. These include CSA certification for Canada, CCC for China, and JIS compliance for Japan. Each certification involves rigorous testing of electrical safety, material quality, and performance stability under various conditions. Our factory maintains all these certifications and regularly updates them to meet evolving standards.

How Do DC Shunts Meet Safety Rules?

A power plant engineer once shared how proper safety-compliant shunts prevented a potential fire incident, saving both lives and millions in equipment.

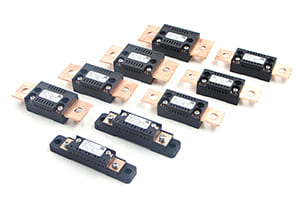

DC shunts meet safety rules through proper insulation design, temperature monitoring capabilities, and overcurrent protection features. Compliance requires regular testing and documentation of safety parameters.

Meeting safety rules involves multiple technical aspects. First, voltage isolation must meet or exceed system requirements - typically 2.5kV to 5kV isolation for industrial applications. Temperature ratings must be clearly marked and tested, with proper derating for high-temperature environments. Our shunts undergo rigorous testing to ensure they maintain safety margins under all specified conditions.

Physical construction also plays a crucial role in safety compliance. Terminal designs must prevent accidental contact with live parts, and mounting arrangements must maintain proper clearance and creepage distances. We implement these features through careful design and selection of materials that meet international safety standards.

Why Follow DC Shunt Standards?

Last month, a manufacturing facility faced heavy fines and production shutdown due to non-compliant shunts. Following standards would have prevented these costly consequences.

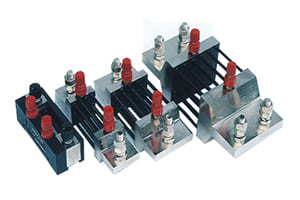

Following DC shunt standards ensures operational safety, legal compliance, and insurance coverage. It protects against accidents, liability issues, and regulatory penalties while maintaining system reliability.

The importance of following standards extends beyond mere compliance. Standards provide a framework for safe operation, maintenance procedures, and emergency responses. They help prevent accidents, reduce liability risks, and ensure consistent performance across different applications and environments.

Standards compliance also affects insurance coverage and legal liability. Many insurance policies require documented compliance with relevant safety standards. In case of accidents or equipment failure, proof of standards compliance can be crucial for claim approval and legal protection. Our documentation system helps clients maintain detailed compliance records for audit and insurance purposes.

Conclusion

Through decades of experience in DC shunt manufacturing and implementation, I've learned that safety standards are the foundation of reliable and secure current measurement systems. Proper certification, compliance with safety rules, and adherence to standards protect not just equipment and operations, but also human lives and business continuity. By choosing properly certified DC shunts and following installation and maintenance standards, you create a safer working environment while ensuring regulatory compliance and system reliability. Remember, the cost of compliance is always lower than the cost of accidents or regulatory violations.