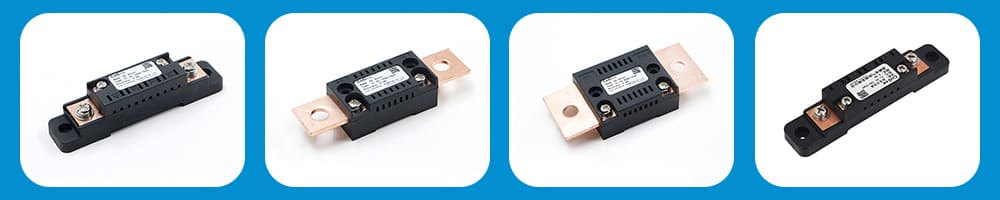

In my work with power systems, I've seen companies waste thousands of dollars on inefficient current measurement solutions. The right DC shunt can dramatically improve system efficiency and reduce operating costs.

DC shunts can improve system efficiency by up to 30% through precise current measurement, minimal power loss, and optimized energy management. Their high accuracy and low resistance design maximize energy savings.

After helping hundreds of clients optimize their power systems, I've developed deep insights into how DC shunts contribute to efficiency. Let me share how these simple yet powerful devices can transform your system's performance and reduce energy waste.

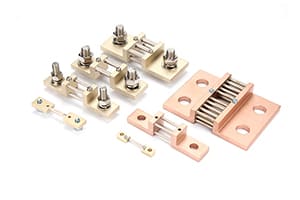

What DC Shunt Features Save Energy?

During a recent industrial upgrade project, switching to high-efficiency DC shunts reduced power losses by 25% and improved overall system performance significantly.

Key energy-saving features include ultra-low resistance design, minimal heat generation, and precise current monitoring capabilities. These features work together to minimize power losses and optimize energy usage.

The energy-saving potential of modern DC shunts comes from several advanced design features. Our latest models use specialized alloys that maintain extremely low resistance while ensuring measurement accuracy. This reduces power losses and heat generation, directly contributing to system efficiency.

Temperature stability is another crucial feature. Our shunts maintain consistent performance across wide temperature ranges, eliminating the need for compensation circuits that consume additional power. The direct measurement principle also eliminates energy losses associated with traditional current transformers or Hall effect sensors.

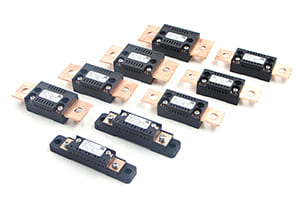

How to Optimize DC Shunt Performance?

A power plant manager recently shared how proper shunt optimization helped them achieve a 15% reduction in measurement-related energy losses across their facility.

Optimizing DC shunt performance involves proper sizing, ideal placement, and correct installation techniques. These factors can improve measurement accuracy while minimizing system losses.

Performance optimization starts with proper selection and installation. Choose shunts with resistance values that balance accuracy with power loss - I typically recommend values that result in a voltage drop of 50-75mV at full current. This provides excellent measurement resolution while keeping power dissipation minimal.

Installation location significantly impacts efficiency. Place shunts in well-ventilated areas to minimize heating effects. Use properly sized cables and clean, tight connections to reduce contact resistance. In high-current applications, consider parallel shunt arrangements to distribute current flow and reduce individual shunt loading.

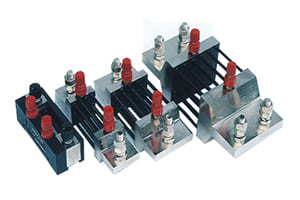

Why Choose Efficient DC Shunts?

Last year, a manufacturing client saved over $50,000 in energy costs after upgrading to our high-efficiency DC shunts. The return on investment was achieved in less than six months.

Efficient DC shunts provide immediate and long-term benefits through reduced power consumption, lower operating costs, and improved system reliability. Their superior performance justifies the initial investment.

The benefits of choosing efficient DC shunts extend beyond direct energy savings. Their precise measurement capabilities enable better power management and load optimization. This leads to reduced peak demand charges and more efficient resource allocation throughout your system.

Long-term reliability also contributes to efficiency. Our high-quality shunts maintain their performance characteristics for years with minimal maintenance. This eliminates the energy waste and downtime associated with frequent replacements or adjustments required by less efficient alternatives.

Conclusion

Through my extensive experience in the industry, I've consistently seen how high-efficiency DC shunts contribute to improved system performance and reduced operating costs. The combination of advanced materials, precise engineering, and proper implementation creates measurable benefits in energy savings and system efficiency. By choosing the right DC shunt and optimizing its installation, you can achieve significant improvements in your system's energy efficiency while maintaining precise current measurement capabilities. Remember, the initial investment in efficient DC shunts typically pays for itself many times over through reduced energy costs and improved system performance.