In my daily consulting work, I often see projects fail simply because engineers chose the wrong shunt size. This simple mistake can lead to overheating, inaccurate measurements, and system failures.

Selecting the right DC shunt size involves considering current rating, voltage drop, power dissipation, and physical space constraints. The proper size ensures optimal performance and prevents system failures.

Having manufactured DC shunts for over three decades, I've developed a comprehensive understanding of sizing requirements. Let me share my expertise to help you choose the right shunt size for your application, avoiding common pitfalls that can lead to costly mistakes.

How to Calculate DC Shunt Requirements?

Last month, a client's power monitoring system failed because they underestimated their shunt's power rating. This costly mistake could have been avoided with proper calculations.

To calculate DC shunt requirements, consider maximum current flow, desired voltage drop, ambient temperature, and safety margins. These factors determine the minimum size needed for safe, accurate operation.

The calculation process for DC shunt requirements involves several critical steps. First, determine your maximum continuous current and any potential surge currents. Add a safety margin of at least 20% to account for unexpected load variations. The voltage drop across the shunt is equally important - typically, we recommend 50mV or 75mV for standard applications, though some situations may require 100mV.

Power dissipation is another crucial factor. Use the formula P = I²R to calculate heat generation. Consider the ambient temperature and available cooling. For example, a 100A shunt with a 75mV drop dissipates 7.5 watts. Ensure your chosen size can handle this heat load while maintaining accuracy. I always recommend adding a 30% safety margin to power calculations.

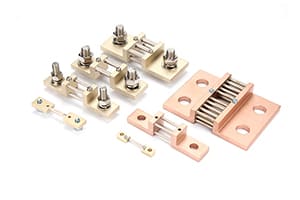

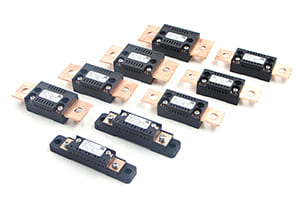

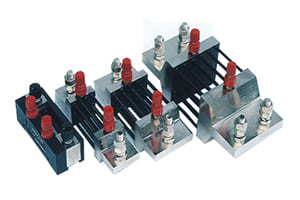

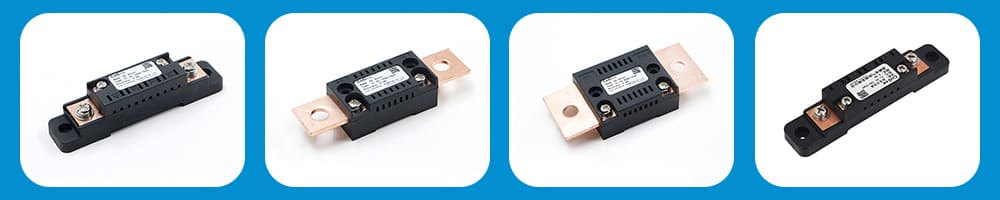

What Determines DC Shunt Dimensions?

A recent industrial client needed to retrofit a DC shunt in a limited space. Understanding dimensional factors helped us design a custom solution that fit perfectly while maintaining performance.

DC shunt dimensions are determined by current capacity, heat dissipation requirements, terminal size, and mounting constraints. These factors must balance physical limitations with performance needs.

Physical dimensions of DC shunts are influenced by multiple factors. The cross-sectional area of the shunt element must be sufficient to handle the current without excessive heating. Higher currents require larger cross-sections, which directly affects the overall size. Terminal size also increases with current rating to ensure proper connection and heat dissipation.

Mounting requirements play a crucial role in dimensional decisions. Adequate clearance is needed for ventilation and terminal connections. In high-current applications, terminal size and spacing must accommodate large cables or bus bars. I always recommend allowing at least 2 inches of clearance around the shunt for proper cooling and ease of maintenance.

Why Does DC Shunt Size Matter?

I once investigated a system failure where an undersized shunt led to a catastrophic meltdown, causing $100,000 in damage. Proper sizing could have prevented this entire incident.

DC shunt size directly impacts measurement accuracy, heat dissipation, and system reliability. Correct sizing ensures safe operation, maintains accuracy, and extends equipment life.

The importance of proper shunt sizing cannot be overstated. An undersized shunt can overheat, leading to drift in resistance values and reduced accuracy. It may also create safety hazards in high-current applications. Conversely, an oversized shunt wastes space and money while potentially reducing measurement sensitivity at lower currents.

Temperature rise is particularly critical. A properly sized shunt should maintain a temperature rise of less than 45°C above ambient under full load. This ensures stable resistance values and maintains measurement accuracy. In my experience, many system failures occur because designers overlook the cumulative effects of continuous operation at elevated temperatures.

Conclusion

Selecting the right DC shunt size is crucial for system performance and reliability. Through my years of experience, I've learned that proper sizing requires careful consideration of electrical requirements, physical constraints, and environmental factors. By following these guidelines for calculating requirements and understanding dimensional factors, you can choose a shunt that provides accurate measurements while ensuring safe, reliable operation. Remember, the small additional cost of a properly sized shunt is insignificant compared to the potential costs of system failure due to improper sizing.