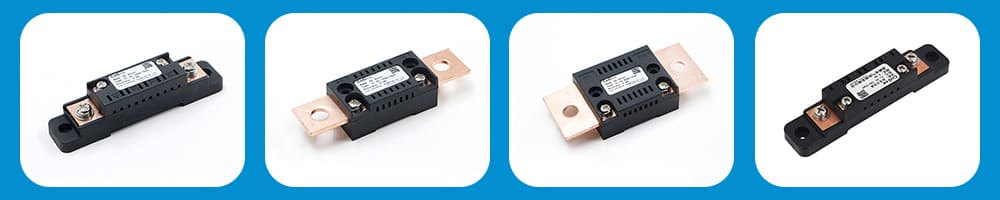

In my three decades of manufacturing DC shunts, the most common question I hear is about accuracy requirements. Choosing the wrong accuracy level can lead to system inefficiencies or failures.

DC shunt accuracy requirements typically range from ±0.5% for basic applications to ±0.01% for precision measurements. Selecting the right accuracy level depends on your application's specific needs and operating conditions.

Through years of working with various industries, I've learned how to match accuracy levels to application requirements. Let me share insights about choosing the right accuracy level and understanding the factors that influence measurement precision.

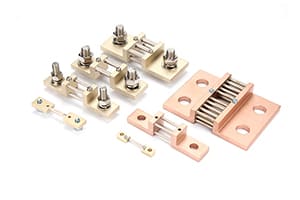

How to Choose DC Shunt Precision Levels?

Every week, I help clients determine their precision requirements. Selecting the right precision level is crucial for both performance and cost-effectiveness.

DC shunt precision selection depends on application requirements, budget constraints, and operating conditions. Higher precision levels offer better accuracy but come with increased costs and installation requirements.

Choosing the right precision level involves careful analysis of application needs. We've developed a systematic approach to help customers select appropriate accuracy levels. Our process considers factors like operating environment, measurement requirements, and system specifications.

We offer multiple precision grades to match different applications. Each grade undergoes specific testing and calibration procedures. Our experience helps customers balance accuracy requirements with practical considerations.

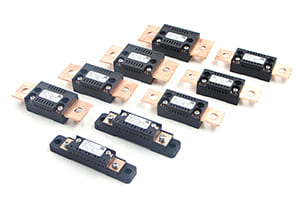

What Affects DC Shunt Accuracy?

Throughout my career, I've observed how various factors impact measurement accuracy. Understanding these influences is crucial for maintaining precise measurements.

DC shunt accuracy is affected by temperature variations, current levels, installation quality, and environmental conditions. These factors can significantly impact the actual measurement precision in real-world applications.

Multiple factors influence shunt accuracy in practical applications. We've conducted extensive research to understand how different conditions affect measurement precision. Our designs incorporate features to minimize the impact of these variables.

Temperature effects often dominate accuracy considerations. We use specialized materials and compensation techniques to maintain accuracy across temperature ranges. Our testing procedures verify performance under various environmental conditions.

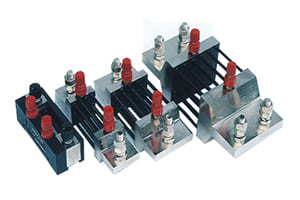

Why Consider DC Shunt Error Rates?

In my consulting work, I emphasize the importance of understanding error rates. Knowing potential measurement errors is crucial for system design and operation.

DC shunt error rates directly impact system performance and reliability. Understanding these rates helps in selecting appropriate safety margins and implementing necessary compensation measures.

Error rate analysis is crucial for system design. We provide detailed error specifications for different operating conditions. Our documentation helps customers understand the practical implications of measurement errors.

Recent innovations in our testing procedures provide more detailed error characterization. We offer comprehensive error analysis for different operating conditions. This information helps customers implement appropriate compensation strategies.

Conclusion

Selecting the right DC shunt accuracy level is crucial for system success. Through careful consideration of precision requirements, understanding influencing factors, and analyzing error rates, you can choose the optimal shunt for your application. My experience has shown that proper accuracy selection is as important as the shunt itself. As measurement requirements become more demanding, understanding accuracy considerations becomes increasingly critical. Taking time to evaluate accuracy needs ensures optimal system performance and reliability.