In my 30 years of manufacturing DC shunts, I've seen many customers struggle with standard shunts when their applications demand higher precision. The difference in performance can be dramatic.

High-precision DC shunts offer superior accuracy up to ±0.01%, compared to standard shunts' typical ±0.5%. They feature specialized materials, advanced temperature compensation, and precise calibration techniques to maintain this exceptional accuracy.

Through decades of experience developing precision measurement solutions, I've learned what truly sets high-precision shunts apart. These specialized components require extraordinary attention to detail in design, materials, and manufacturing. Let me share insights into why these precision instruments are fundamentally different from standard shunts.

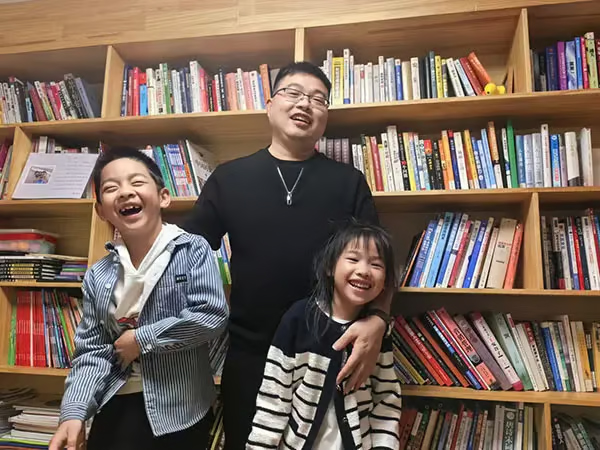

How Are Precision DC Shunts Manufactured?

Every day in our factory, I oversee the complex process of precision shunt manufacturing. The slightest variation in production can affect accuracy significantly.

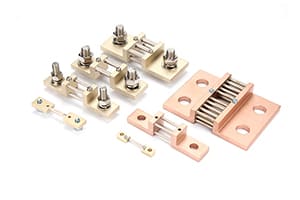

Precision DC shunts require specialized manufacturing processes including precise material composition control, advanced heat treatment, and multi-stage calibration. Each unit undergoes rigorous testing to ensure exceptional accuracy.

The manufacturing process for precision shunts is fundamentally different from standard production. We use specialized alloys with tightly controlled compositions to ensure stable resistance characteristics. Our advanced heat treatment processes reduce internal stresses and improve long-term stability.

Each shunt undergoes multiple stages of testing and calibration. We use state-of-the-art equipment to verify performance under various conditions. Our quality control process includes temperature cycling, load testing, and precision resistance measurements at multiple points.

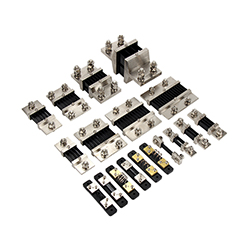

What Features Define Precision DC Shunts?

Throughout my career, customers often ask about the key differences between standard and precision shunts. The distinctions go far beyond basic accuracy specifications.

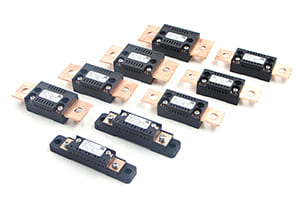

Precision DC shunts are defined by their superior temperature stability, minimal thermal EMF, and exceptional long-term drift characteristics. They incorporate advanced features like multi-point temperature compensation and specialized mounting designs.

The defining features of precision shunts come from years of technological advancement. We use proprietary alloy compositions that offer superior temperature stability and minimal thermal EMF generation. Our designs incorporate sophisticated temperature compensation techniques that maintain accuracy across wide operating ranges.

Advanced features include specialized terminal designs that minimize connection resistance variations. We've developed unique mounting systems that reduce mechanical stress effects on measurement accuracy. These features work together to ensure consistent, precise measurements under all conditions.

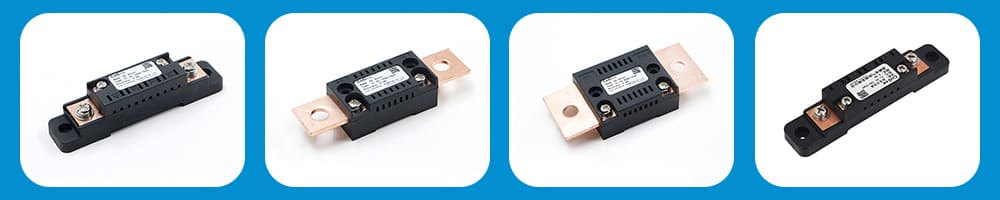

Where Are High-Precision DC Shunts Used?

In my consulting work, I've seen precision shunts become critical in increasingly diverse applications. Their exceptional accuracy enables new possibilities in many industries.

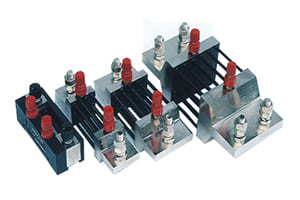

High-precision DC shunts are essential in calibration laboratories, semiconductor manufacturing, aerospace testing, and advanced research facilities. Their superior accuracy makes them ideal for applications where standard shunts cannot meet performance requirements.

The applications for precision shunts continue to expand as technology advances. We supply these devices to national standards laboratories for calibration work. They're used in semiconductor manufacturing for precise process control and testing.

Our precision shunts play crucial roles in aerospace testing facilities and advanced research laboratories. The high accuracy enables new capabilities in electric vehicle development and renewable energy systems. Each application benefits from the exceptional stability and precision these specialized components provide.

Conclusion

High-precision DC shunts represent the pinnacle of current measurement technology. Through specialized manufacturing processes, advanced features, and careful material selection, these devices achieve exceptional accuracy levels that standard shunts cannot match. My experience has shown that the investment in precision shunts pays dividends in applications requiring the highest level of measurement accuracy. As technology continues to advance, the role of high-precision shunts becomes increasingly important in enabling new capabilities and ensuring measurement accuracy in critical applications.