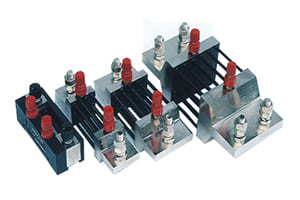

In my years of supplying DC shunts to the EV industry, I've seen many manufacturers struggle with component selection. Poor shunt choices can lead to battery damage, charging issues, and safety risks.

Selecting the right DC shunt for EV applications requires careful consideration of current range, accuracy, temperature stability, and voltage isolation. The right choice ensures safe operation and optimal performance of EV systems.

Having worked with major EV manufacturers worldwide, I understand the critical role of DC shunts in electric vehicle systems. The growing demand for longer range and faster charging creates new challenges for current measurement. Let me share my expertise on choosing the right DC shunts for various EV applications.

What DC Shunt Specs Matter for EV Systems?

Every week, I consult with EV engineers about specification requirements. The wrong specifications can compromise vehicle performance and safety.

Key DC shunt specifications for EV systems include current capacity, voltage isolation, temperature coefficient, and response time. These parameters directly impact battery management and vehicle performance.

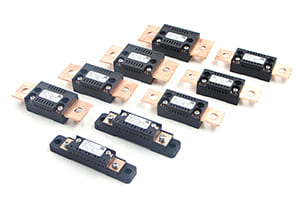

Through extensive testing and field experience, we've identified critical specifications for EV applications. Current capacity must match both normal operating conditions and peak demands during acceleration. Voltage isolation requirements have become more stringent with higher battery voltages in modern EVs.

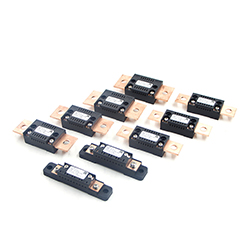

Our latest designs incorporate features specifically for EV applications, including enhanced EMI protection and faster response times. We've developed specialized testing procedures that simulate real-world EV conditions to ensure optimal performance. These innovations help manufacturers meet increasingly demanding vehicle specifications.

How Do DC Shunts Protect EV Batteries?

Throughout my career, battery protection has been a primary concern for EV manufacturers. Effective current monitoring is essential for preventing battery damage and ensuring safety.

DC shunts protect EV batteries by providing precise current monitoring during charging and discharging. Their accurate measurements enable battery management systems to prevent overcharging and excessive discharge rates.

Battery protection through DC shunts involves sophisticated monitoring and control systems. Our shunts provide continuous current measurement with exceptional accuracy, enabling real-time battery protection. We've developed specific models that integrate seamlessly with battery management systems.

Recent advances in our shunt technology have improved response times and temperature stability. These improvements enable faster detection of fault conditions and more reliable battery protection. Our latest designs include enhanced isolation features to protect sensitive monitoring circuits from high battery voltages.

Which DC Shunt Models Suit EV Charging?

In my experience with EV charging applications, selecting the right shunt model is crucial for safe and efficient charging. The demands of fast charging create unique challenges for current measurement.

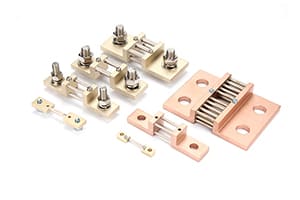

DC shunt models for EV charging must handle high current loads, maintain accuracy during rapid changes, and provide excellent thermal stability. Models with enhanced cooling and fast response times are ideal for charging applications.

Selecting the right model for EV charging requires understanding specific application requirements. Our charging-optimized shunts feature enhanced thermal management and robust construction. We've developed models specifically for different charging levels, from standard AC charging to ultra-fast DC systems.

These specialized designs incorporate advanced cooling features and optimized geometry for high-current applications. Our latest models include integrated temperature monitoring and enhanced connection systems for reliable long-term operation. These features ensure accurate current measurement even during extended fast-charging sessions.

Conclusion

Selecting the right DC shunt for EV applications requires careful consideration of multiple factors. Through proper specification matching, battery protection features, and charging capabilities, these components play a crucial role in EV system performance and safety. My experience has shown that successful EV implementations depend heavily on choosing the right shunt models and specifications. As EV technology continues to advance, the importance of proper shunt selection becomes increasingly critical. Working with experienced manufacturers who understand these requirements is essential for achieving optimal results in EV applications.

Online | Privacy policy

Online | Privacy policy