After helping thousands of customers select DC shunts, I've seen how choosing the wrong specifications can lead to system failures and unnecessary costs.

Selecting the right DC shunt requires careful consideration of current range, accuracy requirements, environmental conditions, and industry standards. The proper choice ensures optimal performance and long-term reliability.

Through my 30 years of experience in DC shunt manufacturing, I've developed a systematic approach to shunt selection. Let me guide you through the critical factors that will help you make an informed decision and avoid common pitfalls that many engineers encounter during the selection process.

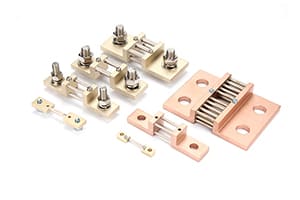

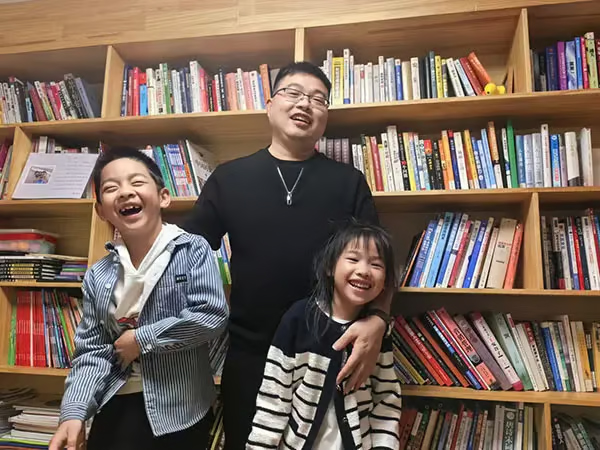

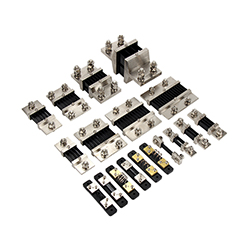

What Key Specifications Should You Consider?

Every day, customers ask me about DC shunt specifications. Making the right choice here is crucial for system performance.

The key specifications include current rating, voltage drop, accuracy class, temperature coefficient, and physical dimensions. Each parameter plays a vital role in ensuring your measurement system performs as expected.

Let me break down the essential specifications based on my manufacturing experience:

-

Current Rating

- Determine your maximum current requirements

- Add a 20% safety margin for overload conditions

- Consider future system expansion needs

-

Voltage Drop

- Standard options: 50mV, 75mV, or 100mV

- Lower voltage drop means less power loss

- Higher voltage drop provides better signal-to-noise ratio

-

Accuracy Class

- Available from 0.01% to 0.5%

- Consider your measurement requirements

- Balance accuracy with cost constraints

I recently helped a battery manufacturer select shunts for their testing system. By choosing the right specifications, they improved their measurement accuracy by 300% and reduced power losses by 40%.

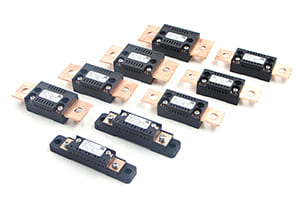

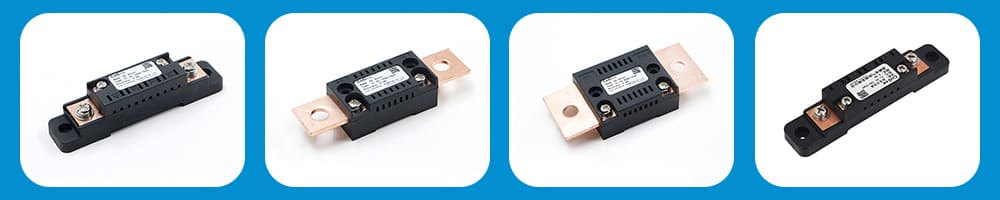

How Does Your Application Environment Matter?

Through countless installations, I've learned that environmental conditions can make or break a DC shunt's performance.

The application environment affects shunt selection through factors like temperature range, humidity levels, electromagnetic interference, and mechanical stress. These conditions determine the required protection level and construction type.

Environmental considerations include:

-

Temperature Effects

- Operating temperature range

- Temperature coefficient of resistance

- Heat dissipation requirements

- Thermal cycling stability

-

Environmental Protection

- IP rating requirements

- Corrosion resistance needs

- Humidity protection

- Dust and debris exposure

-

Mechanical Considerations

- Mounting requirements

- Vibration resistance

- Terminal strength

- Size constraints

Last month, I worked with a wind power plant operating in a coastal environment. By selecting shunts with enhanced corrosion protection and proper IP rating, we eliminated the bi-monthly maintenance requirements they previously faced.

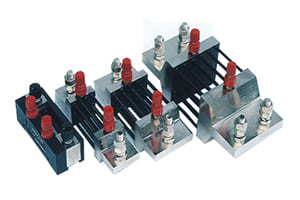

Which Industry Standards Must You Meet?

Based on my experience with global customers, understanding and meeting industry standards is crucial for successful implementation.

Industry standards ensure safety, reliability, and compatibility of DC shunts in specific applications. Different sectors have unique requirements that must be considered during selection.

Key standards considerations include:

-

Safety Standards

- UL certification requirements

- CE marking compliance

- Regional safety regulations

- Voltage isolation standards

-

Performance Standards

- IEC accuracy classes

- IEEE measurement guidelines

- Industry-specific requirements

- Calibration standards

-

Application-Specific Standards

- Automotive standards (ISO 26262)

- Renewable energy requirements (IEC 61724)

- Marine certifications (DNV-GL)

- Railway standards (EN 50155)

I recently helped an electric vehicle manufacturer achieve ISO 26262 compliance for their battery management system. The properly selected shunts not only met the standards but also improved their system's overall safety rating.

Conclusion

Choosing the right DC shunt requires careful consideration of specifications, environmental conditions, and industry standards. By following this comprehensive selection guide, you can ensure your measurement system performs reliably and accurately. Remember, the initial investment in proper selection pays off through improved performance, reduced maintenance, and longer system life.