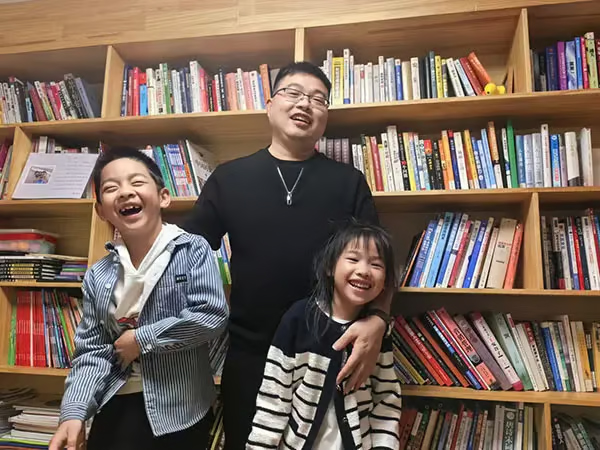

As a DC shunt manufacturer with 30 years of experience, I've seen many engineers struggle with current measurement solutions. The confusion often leads to costly mistakes and system failures.

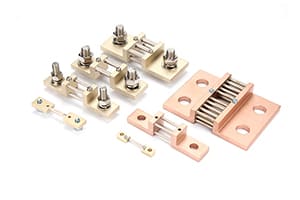

A DC shunt is a precision resistive device designed to measure high electrical currents by creating a small voltage drop proportional to the current flowing through it. It's the most reliable and cost-effective solution for current measurement in DC systems.

In my years of working with customers across various industries, I've found that understanding DC shunts is crucial for anyone involved in electrical systems. From renewable energy to electric vehicles, these simple yet powerful devices play a vital role in ensuring system safety and efficiency. Let me share my expertise to help you understand why DC shunts are indispensable in modern electrical applications.

How DC Shunts Work?

Every week, I receive calls from engineers asking about the working principle of DC shunts. It's a crucial question that deserves a clear, practical explanation.

DC shunts work by using Ohm's Law - they create a precise voltage drop across a low-resistance element when current flows through it. This voltage drop is directly proportional to the current, making measurement simple and accurate.

The working principle of DC shunts is based on fundamental electrical laws, but their implementation requires precise engineering. From my manufacturing experience, I can tell you that the key lies in three critical aspects. First, we use specialized alloys like Manganin that maintain stable resistance across temperature changes. Second, the design must ensure uniform current distribution through the shunt. Third, the connection points must be optimized for minimal contact resistance.

I remember a case where a customer was struggling with inconsistent current readings. After examining their setup, we discovered they were using an incorrectly sized shunt. By implementing the proper shunt with the right resistance value, their measurement accuracy improved from ±5% to ±0.1%. This kind of precision is what makes DC shunts so valuable in critical applications.

DC Shunt Applications Explained?

In my three decades of experience, I've seen DC shunts transform from simple measuring tools to critical components in advanced electrical systems.

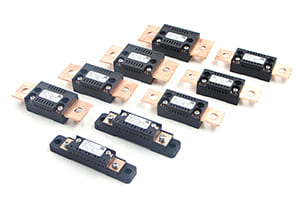

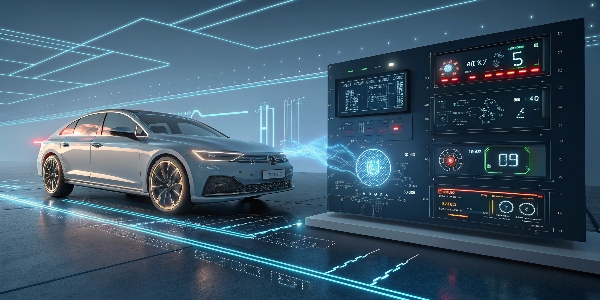

DC shunts are essential in various applications, from battery management systems and electric vehicles to renewable energy installations and industrial automation. Their versatility and reliability make them the preferred choice for current measurement.

Through my work with different industries, I've observed how DC shunts excel in various applications. In electric vehicle manufacturing, our shunts monitor battery current with high precision, ensuring optimal charging and discharging cycles. In solar power installations, they help maintain system efficiency by providing accurate current measurements for power optimization.

The versatility of DC shunts becomes evident when you consider their role in different sectors. In industrial automation, they provide crucial feedback for motor control systems. In renewable energy, they monitor power generation and consumption. In research laboratories, they enable precise current measurement for experimental setups. Each application benefits from the shunt's core advantages: high accuracy, reliability, and stability.

Why Use DC Shunts?

After supplying DC shunts to thousands of customers, I've gathered compelling reasons why they remain the top choice for current measurement.

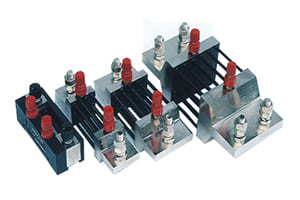

DC shunts offer unmatched advantages: high accuracy, excellent stability, simple operation, and cost-effectiveness. They provide reliable current measurement without the complexity of other solutions.

The benefits of using DC shunts extend far beyond basic current measurement. From my experience working with various industries, I can highlight several key advantages. First, their simple design means fewer points of failure compared to electronic solutions. Second, they're incredibly durable - I've seen our shunts operate reliably for decades in harsh industrial environments. Third, they provide exceptional accuracy without requiring complex calibration procedures.

I recently worked with a renewable energy company that switched from Hall effect sensors to our DC shunts. The result? They reduced their measurement system costs by 40% while improving accuracy. Their maintenance team particularly appreciated the simplicity of troubleshooting and the lack of electronic components that could fail.

Conclusion

DC shunts are fundamental components in modern electrical systems, providing accurate current measurement, system protection, and performance optimization capabilities. Their reliability, precision, and cost-effectiveness make them irreplaceable in various applications, from electric vehicles to renewable energy systems. As technology advances, the role of DC shunts continues to evolve, making them even more valuable in our increasingly electrified world.